Assuming an individual needs to have subjective plastic materials, they can contact the organizations giving extrusion profiles to their clients. The merchants keep a wide scope of items that is appropriate for the client's requirements. Before, individuals expected to trust that extended periods will make a solitary result of plastic. The things were implicit separate segments and pieces. Interestingly, individuals can accomplish the items quickly by deciding on this strategy for creation.

Individuals can acquire items like lines, boundary fences, window outlines, separators, and so forth, with the plastic extrusion process. The quality of the items is supreme as the manufacturers use high-grade synthetic granules to make their products. one can save a lot of time and money if one buys these products. in recent times many people are opting for this material

Plastic materials are an awful conveyor of warmth and power. Subsequently, individuals don't fear introducing these things in their homes. The organizations fabricate items having various sizes, surfaces, thicknesses, and lengths. At the point when they produce the wares in an outrageous amount, there is insignificant wastage. Hence, they save a ton on making the items. If the creation costs become low, the selling cost of the item naturally lowers down.

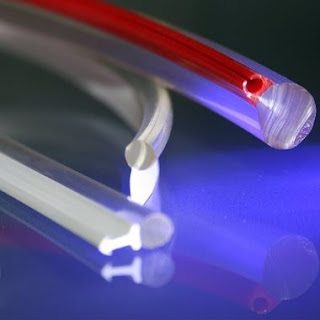

These individuals keep an exact consistency on their items if they select this strategy for creation. The organizations blend different added substances to the first material to expand the solidness, imperviousness to fire, decrease contact, and static of the item. Individuals can have a protecting layer on the wires by reaching specialists. The makers lead a co-expulsion measure by adding at least two machines to a sing creation had. This cycle is valuable in creating numerous layer items. If an individual is looking for acceptable quality plastic items at a reasonable value, they can contact the renowned providers of their territory.