Low Smoke Zero Halogen (LSZH) electrical conduit systems are widely used in environments where fire safety and smoke toxicity are major concerns. A key element contributing to the performance and versatility of LSZH electrical conduits and accessories is the use of custom extrusion profiles during manufacturing. These profiles play a crucial role in improving structural integrity, efficiency, and safety across various applications.

What Are Extrusion Profiles?

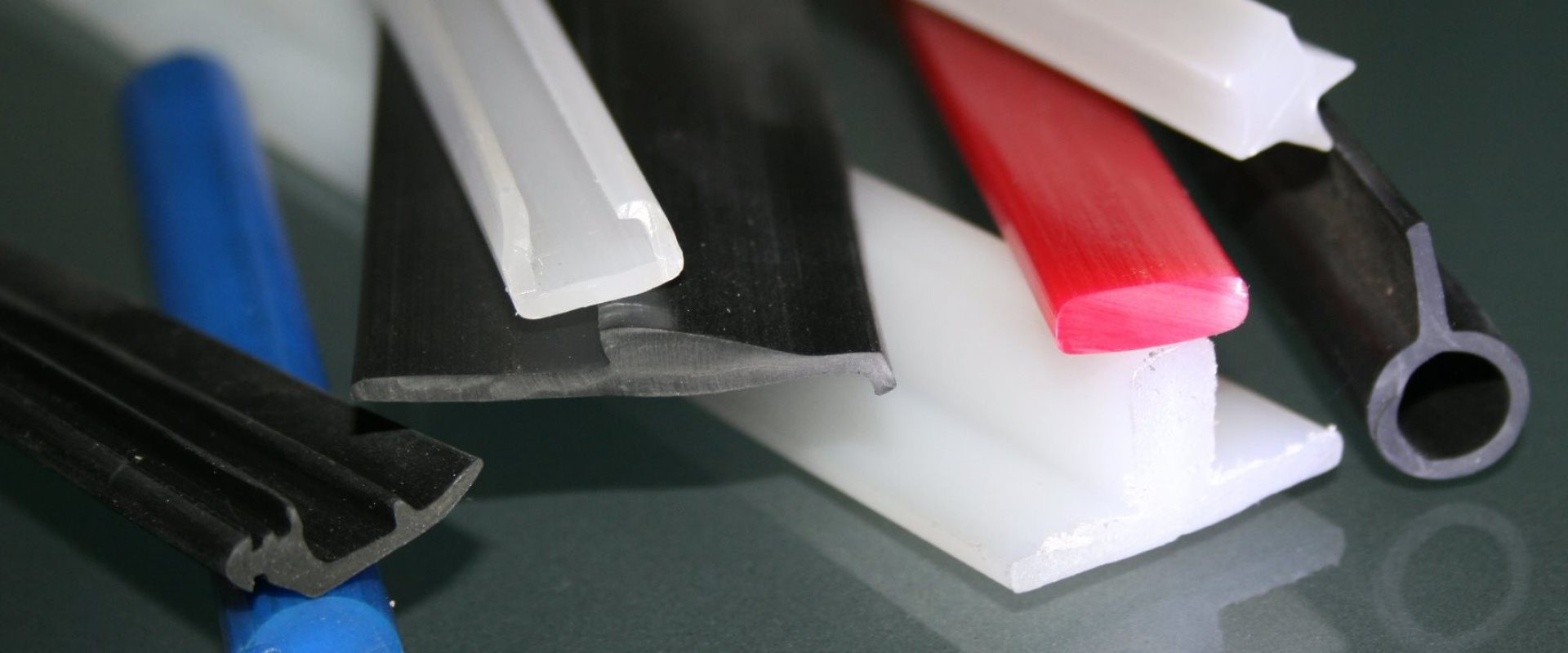

Extrusion is a manufacturing process where heated material—like LSZH polymer—is pushed through a die to create a specific cross-sectional shape. These custom shapes, or extrusion profiles, can be tailored to meet the technical and installation needs of conduit systems, offering everything from basic round profiles to more complex geometries for fittings, joints, brackets, and bend supports.

Enhancing Mechanical Strength and Flexibility

One of the biggest advantages of using customized extrusion profiles is the ability to reinforce mechanical properties. For LSZH conduits, this means added resistance to impact, compression, and environmental stress. Different profiles can be engineered to allow greater flexibility in routing cables while maintaining the necessary rigidity to prevent collapse or deformation under load.

For example, ribbed or corrugated extrusion profiles increase flexibility and bend radius without sacrificing strength, making installation easier, especially in tight spaces or curved pathways.

Improving Fire Performance and Safety

The key reason LSZH materials are preferred is their low smoke and non-toxic emission properties during combustion. Custom extrusion profiles ensure that the conduit walls maintain consistent thickness and structure, which helps preserve fire-resistant characteristics throughout the length of the product. Accurate profiles also reduce gaps or inconsistencies that may allow flame spread or smoke leakage, especially at joints and fittings.

By investing in well-engineered profiles, manufacturers can deliver conduit systems that meet modern building codes, support efficient installation, and protect lives and assets in the event of fire.