Because they can produce high-quality products with a continuous cross-section, plastic extrusion profiles from top plastic extruders have been the mainstay of plastic production in Australia. As the industrial sector has grown globally, the introduction of plastic material has been essential to sustaining high productivity because of its versatility. Reputable manufacturers' extrusion profiles are utilised for a range of equipment applications in the mining and construction industries.

LSZH rigid conduit pipe and conduit tunnel are widely considered the industry standard for the installation of electrical lines in a range of residential, commercial, and industrial facilities. Extrusion profiles are created from a range of plastics or polymers, such as HDPE, polystyrene, polypropylene, etc., according to the requirements of the industry. To create these profiles, the raw material must be put through a machine with high pressure to mould it into the right shape. Additionally, top producers were able to combine two distinct materials using a technique called co-extrusion.

List of Plastic Products Made Using Different Techniques

Corrugated Tubing: Due to their strength, flexibility, and parallel ridges, these tubes may be utilised for wiring and other applications. These tubes can sometimes even perform better than PVC due to their small volume and excellent safety features.

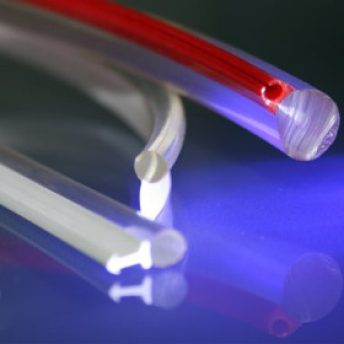

Co-Extrusion Profiles: By combining two distinct polymers, this enables the brand to employ materials that are frequently superior. The finest wraps for shielding the contents from various weather conditions are plastic spiral wraps. The substance may even shield the contents from ultraviolet light.

The materials used to shield the electrical lines positioned close to the solar panels are called solar conduits. Because these containers shield the wires from the sun's UV rays, they are used to package them.

Plastics are used extensively in a variety of sectors for electrical wire systems and other processes. If you want the greatest plastic product on the market or want to collaborate with top firms that provide bespoke product creation, get in touch with the companies that manufacture these items.