In recent times, plastic extrusion profiles are one of the popular methods of manufacturing plastic items. The melting of raw plastic and forming it into a continuous shape is known as extrusion. Usually, this method produces items in high volume. Most reputable manufactures use this method for creating quality products. Due to its numerous advantages, this method has become a standard process for producing plastic items. The manufacturers shape the material with a rigid frame called a pattern. It is an efficient and cost-effective way to create plastic parts and structures in large volume.

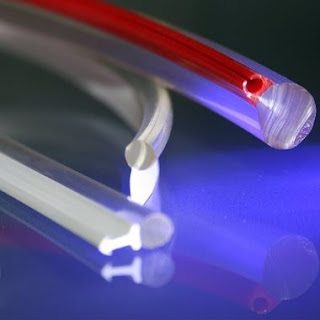

The plastic profiles involve placing plastic in the extruder—the materials continuously forward through rotating screws inside the heated barrel. The friction and heat always soften the inside contents. The softened plastic throws out through a die in cool water, which solidifies the product. Some of the standard items through the extrusion profile are rain gutters, PVC piping, deck railing, plastic film and sheets, and thermoplastic coatings.

One of the prominent reasons for referring to this process is that it allows the item's flexibility. Due to constant cross-sectioning, extrusion moulding can produce complex shapes and sizes. This process enables being creative, as one can order the product of varying size, colour, thickness, and texture. It is suitable for achieving versatile items.

This method allows for post-extrusion alterations. When plastic leaves the extruder, it remains hot, which is perfect for manipulation. Manufacturers can use the dies, rollers, and various tools to alter the shape according to the need. In a way, it offers a greater scope of customisation.

The products from this method come at a cost-effective price. This process uses thermoplastic which repeatedly undergoes melting and hardening. Other moulding processes usually dispose of the leftover materials, but this method uses the supposedly discarded item. The low raw material and disposal cost leads to the reasonable price of resultant products. If you are looking for this process, get in touch with the leading specialists in the city.