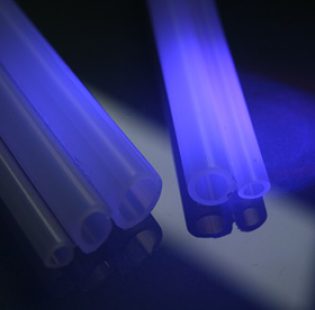

Verified plastic profiles indicate that products made from pelmet rubber—which involves putting molten plastic past a die to generate a shape with a preset cross-section—are important. It is an effective way to produce a variety of shapes and is necessary for usage in both home and commercial items. Extrusion is only possible with thermoplastic materials since other materials must be melted into a solid state and then resolidified. This kind of plastic is suitable for recycling both old items and scraps because of its characteristics.

Why You Should Purchase Plastic Extrusion Straight from Manufacturers:

For several reasons, experts advise poly tubing suppliers straight from reliable producers. One of the reasons for this is cost-effectiveness, since things may be obtained at a more competitive price by doing away with middlemen like wholesalers or merchants.

They also uphold stringent quality control procedures throughout the production cycle. Customers will be guaranteed high-quality items that satisfy industry requirements and function dependably thanks to this.

Second, trustworthy suppliers can offer specially designed plastic processing solutions to satisfy project demands. Their extensive choice of alternatives ensures a customised product that meets clients' particular requirements. Alternatives include picking out the material, profile design, measurements, colours, and finishes.

Examine the Various Benefits of a Canopy Pelmet

- Insulating material: Curtain pelmets reduce draughts and act as a barrier between the window and the room, keeping the area cool in the summer and warm in the winter.

- Window pelmets: They might aid in reducing light and noise, enhancing your room's comfort and resting environment.

- Aesthetic appeal: By bringing a hint of refinement and elegance, curtain pelmets offer your room a polished appearance.

It's possible to prevent wasting extra material by choosing the precise width of piping that you want. Your prices will go down dramatically if you can wrap your items in just one container and combine delivery options.