The plastic extrusion method, which is widely recognised in the industry for producing high-quality goods, is used to make LSZH rigid conduit pipe. Because it can produce large quantities of items quickly, this technology has become the industry norm. Since plastics can be used for so many different things, including pipes, tubes, wraps, and more, they have taken over every industry worldwide.

Corrugated tubes and corrugated split tubing are two examples of the many extrusion profiles that are produced using the extrusion process. Every piece of machinery employed in the process has the potential to produce certain product types and sizes, including electrical conduit fittings. LSOH corrugated conduit, PVC solar conduit, split loom tube solar conduit, polypropylene loom tube, polyamide conduit, and more well-known products may be made using the plastic extrusion process.

A List of Some of the Main Items Made Using Extrusion Technology

Corrugated Tubing: These items are utilised for a number of purposes, including solar farm installations, cable cleaning, automotive wiring protection, and industrial wiring protection. Among the many benefits of these goods are UV and high-temperature heat stabilisation.

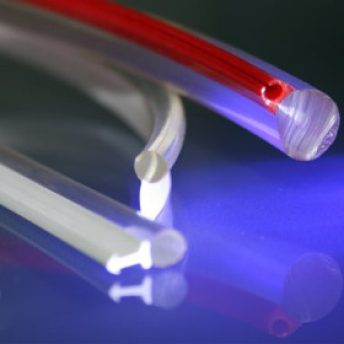

Co-Extrusion Profiles: These are manufactured products that are created by joining two plastic pieces in a die-cast process. The items may have much superior qualities as a result of the two components being combined. This method may be used to create products that combine the properties of two different types of plastic in layers, depending on the requirements.

Poly Tubing: HDPE and LDPE are two examples of the several polythene polymers used to make these tubes. These items can be used as food and beverage transfer devices, transfer hoses, etc.

Flexible PVC: Because of its unique qualities, flexible PVC is widely employed in the medical industry in addition to being used for insulation. Because of its features, this product may be used as a liquid-carrying hose. It is constructed from V75 or V90HT cable-grade material.

Plastics' low cost and widespread manufacture have caused a global revolution in the industrial sector. Speak with the top companies to learn more about the different products and make decisions based on your company's needs.