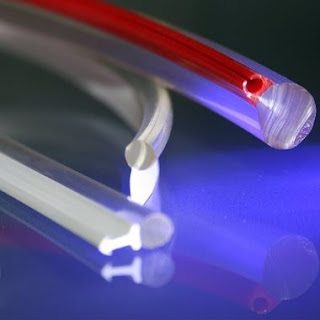

The plastic extrusion process is explicitly deployed for producing an extensive variety of plastic items, right from pipes and tubes to wire insulations and plastic sheets. The procedure usually involves pressing thermoplastic material to produce fixed cross-sectional profiles.

The General Mechanism of Plastic Extrusion Process

Plastic extrusion profiles are usually prepared by gravity feeding resin, or, raw thermoplastic material from the top mounted hopper into the barrel. At times, additives, such as UV inhibitors and colourants are incorporated in the pellet or liquid form. The process offers much in common with the plastics injection moulding technique.

The resin usually leaves the screw and travels through the reinforced screen for removing all contaminants. The resin enters the due after passing through the breaker plate. It is the die that gives the final product its shape or profile so that the molten plastic evenly flows through a cylindrical profile to imbibe the required product’s profile shape.

If the flow gets disrupted at this stage the product exhibits unwanted stress at specific points in the profile. Upon cooling, the stress can cause warping. With a continuous profile, consumers can produce any shape that can be imagines. The extrudate is usually pulled through a water bath for cooling it down. Plastics being excellent thermal insulators are challenging to cool swiftly. In sheet extrusion process, factory units often deploy a set of cooling rollers to cool down the sheet as it exists the extruder.

Popularity of Plastic Extrusion process

Plastic extruders are often extensively used for preparing the raw materials or recycled plastic waste. It is essentially a manufacturing technique where the metal is confined in a closed cavity. Thereafter it is allowed to flow through only one opening that the metal takes the opening shape.

To conclude, the process is well-known for its operational flexibility, high production volumes, good mixing ability, consistency and impressive surface finishing.