Electrical safety standards have evolved significantly as buildings become more complex and densely occupied. One material that has gained importance in modern electrical installations is LSZH electrical conduit. LSZH stands for Low Smoke Zero Halogen, a specification designed to reduce toxic emissions and smoke generation in the event of a fire. Unlike traditional PVC conduits, LSZH conduits are manufactured without halogens such as chlorine or fluorine, which are known to release corrosive and harmful gases when burned.

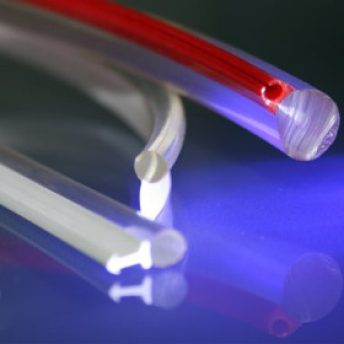

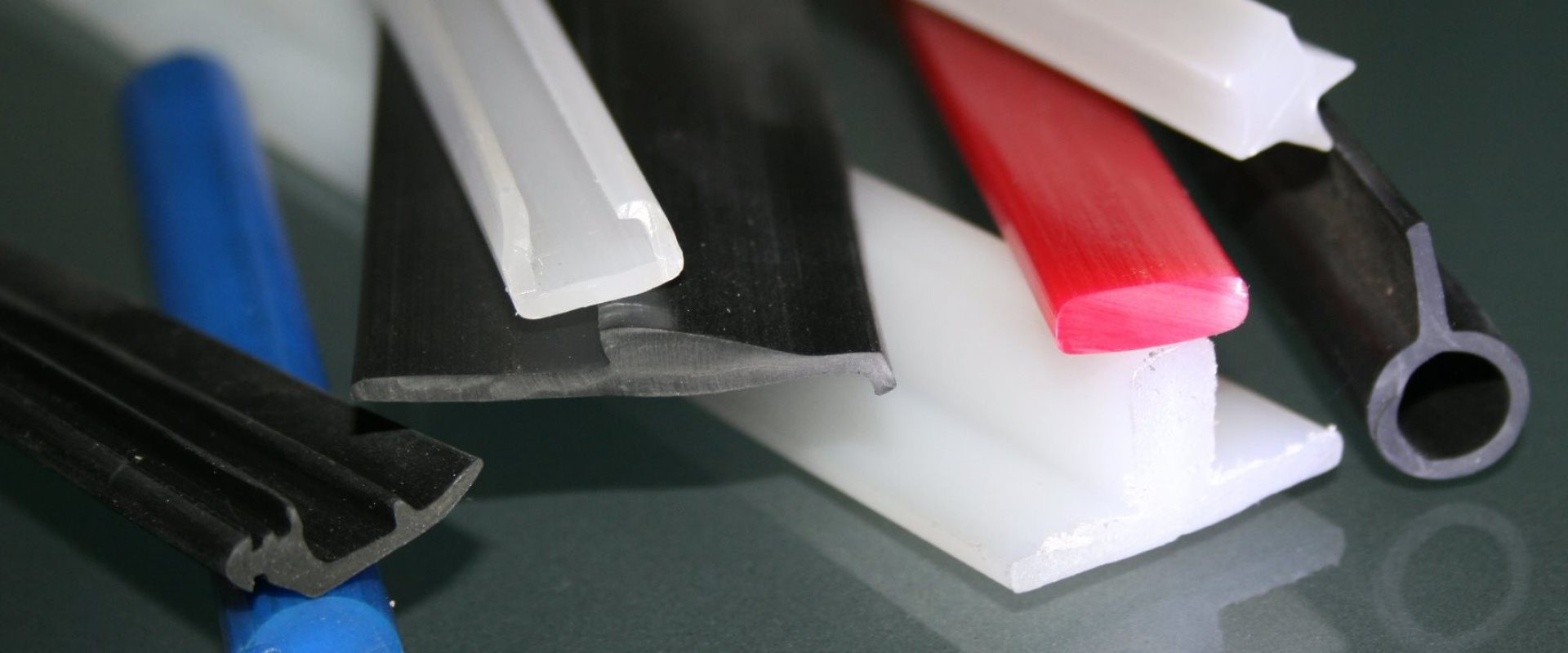

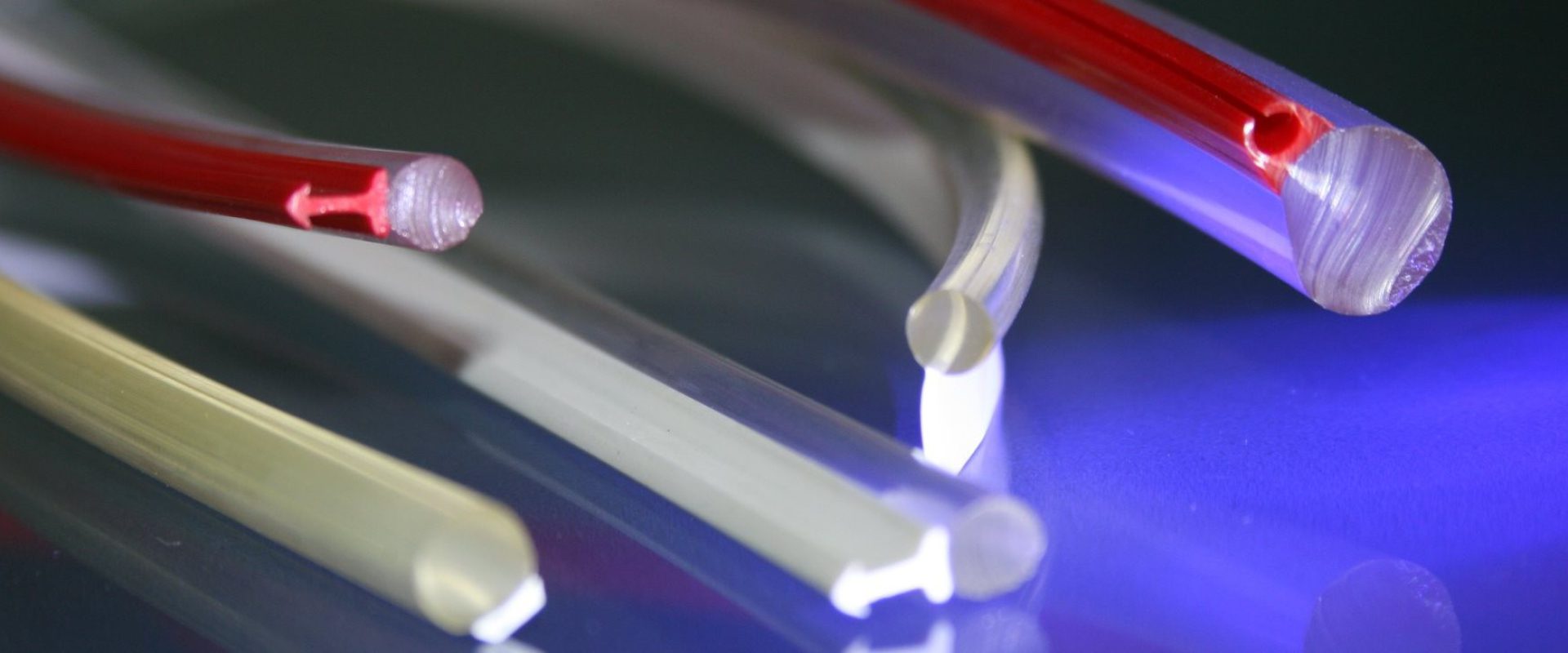

In many installations, LSZH conduits are supplied in standard sizes, but specialised projects often require custom profiles and extrusions to suit unique routing, space constraints, or integration with specific electrical systems. These tailored conduit solutions are commonly used in commercial, industrial, and infrastructure projects where standard conduit designs are not sufficient to meet performance or compliance requirements.

Key Characteristics of LSZH Electrical Conduit

LSZH electrical conduits are engineered with safety as the primary focus. When exposed to fire, they emit very low levels of smoke and do not release halogenated gases. Additionally, the absence of corrosive gases helps protect sensitive electrical equipment, metal structures, and building systems from long-term damage following a fire event.

From a mechanical perspective, LSZH conduits offer good impact resistance, flexibility, and durability, making them suitable for both surface-mounted and concealed installations. They are also compatible with modern cable management systems used in high-density electrical environments.

Why LSZH Matters in Fire-Sensitive Environments

Traditional conduits can produce thick, toxic smoke that spreads rapidly through buildings, posing serious risks to occupants and emergency responders. LSZH conduits minimise this risk by maintaining clearer air paths and reducing overall toxicity. This is particularly important in enclosed or underground spaces where smoke accumulation can be deadly within minutes.

Where LSZH Electrical Conduit Is Commonly Required

LSZH conduits are often specified in locations where occupant safety and asset protection are critical. These include:

- Public buildings such as hospitals, schools, and universities

- Transport infrastructure, including tunnels, rail stations, and airports

- Data centres and telecommunications facilities

- High-rise commercial offices and mixed-use developments

- Industrial plants with large electrical networks

Understanding where and why LSZH conduit is required helps designers, contractors, and building owners make informed decisions that prioritise safety, compliance, and long-term performance.