When it comes to electrical installations, selecting the right type of conduit can make a significant difference in terms of safety, durability, and performance. Two commonly used options are flexible nylon conduit and LSZH electrical conduit and accessories. Understanding the differences between these two can help you choose the most suitable solution for your specific application.

What is LSZH Electrical Conduit?

LSZH stands for Low Smoke Zero Halogen. These conduits are constructed from materials that, under fire, do not produce dense smoke or poisonous fumes. This feature makes LSZH electrical conduit and accessories an excellent choice for use in enclosed spaces, such as data centers, tunnels, hospitals, and public buildings where fire safety and air quality are critical.

The main advantages of LSZH conduits include:

- Reduced smoke emission: Minimizes visibility issues during evacuation.

- Non-toxic gases: Does not release harmful halogens when burning.

- Compliance with fire safety standards: Often required in high-safety environments.

Additionally, LSZH electrical conduit accessories such as fittings, connectors, and junction boxes are designed to match the same fire-safe characteristics, ensuring a consistent and reliable installation.

What is Flexible Nylon Conduit?

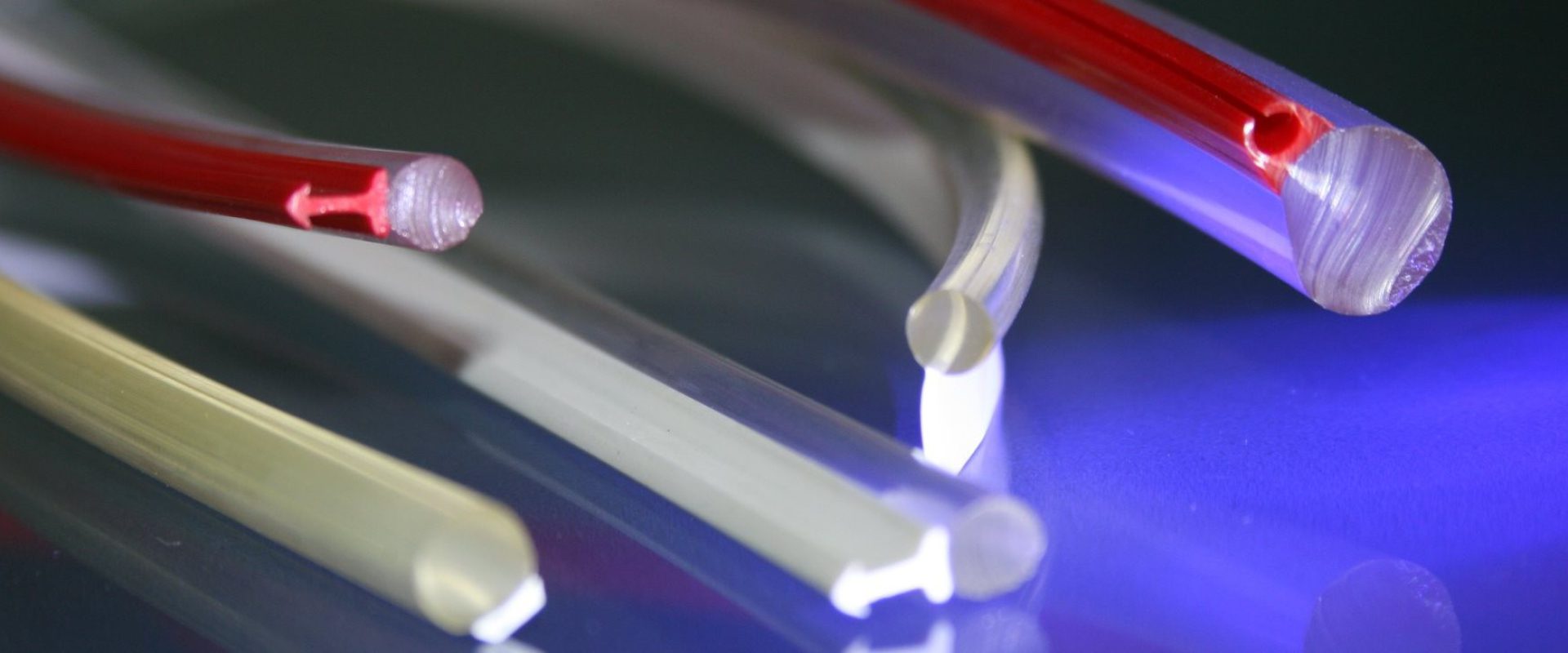

Flexible nylon conduit is known for its flexibility, mechanical strength, and resistance to abrasion, oil, and chemicals. These conduits are perfect for applications involving tight bends, movement, or vibration. They are frequently utilised in robotics, industrial machines, automotive applications, and general cable protection.

Key benefits of flexible nylon conduits include:

- High flexibility: Perfect for moving parts or compact spaces.

- Durability: Resistant to wear and environmental factors.

- Easy to install: Lightweight and flexible enough to accommodate a variety of layouts.

Both LSZH and flexible nylon conduits serve important roles in modern electrical systems. Understanding their unique properties helps ensure compliance with safety standards while also providing efficient and long-lasting cable management solutions. Always consult with a certified professional to determine which conduit system fits your application best.