On the off chance that an individual needs to have subjective plastic materials, they can contact the organisations giving plastic tube to their clients. The dealers keep a wide scope of items that is appropriate for the client's necessities. Previously, individuals expected to trust that extended periods will make a solitary result of plastic. The things were underlying separate areas and pieces. Conversely, individuals can achieve the items at the flicker of an eye by settling on this strategy for creation.

Individuals can obtain various items through extrusion process like corrugated split tubing, pipes, walls, window outlines, separators, etc. Individuals can without much of a stretch spot the sections in the private and business regions. Individuals don't decide on the metal ones since they heat up quickly and makes harm the wires inside them.

Plastic materials are non-conductor of warmth and power. Hence, individuals don't dread to introduce these things in their homes. The organisations fabricate items having various sizes, surfaces, thicknesses, and lengths. At the point when they produce the items in an outrageous amount, there is an insignificant wastage. Thusly, they save a great deal on making the items. In the event that the creation costs become low, the selling cost of the item consequently lower down.

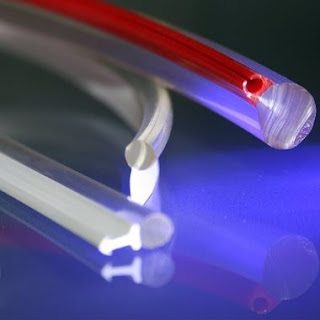

These individuals keep an exact consistency on their items on the off chance that they select this strategy for creation. The organisations blend different added substances to the first material to expand the sturdiness, imperviousness to fire, decrease erosion, and static of the item. Individuals can have a protecting layer on the wires by reaching specialists.

The makers lead co-expulsion measure by adding at least two machines to a sing creation had. This cycle is valuable in delivering various layer items. On the off chance that an individual is looking for acceptable quality plastic items at a reasonable value, they can contact the main providers of their territory.