The plastic extrusion process includes the usage of heavy-duty machinery to produce substances having a continuous profile. Small thermoplastic granules or pellets are placed into the hopper of the extrusion machine. The polymer flakes meltdown in the heaters of the barrel. These molten substances are stuffed into a die; here, the objects attain their real structure and are hardened during the cooling process.

A majority of the manufacturers use extrusion profiles in Melbourne to produce plastic products having continuous shapes. People cannot obtain sheets or films by this fabricating method. This manufacturing method is used to obtain materials having the same shapes and structure; an individual can produce substances like pipes, tubing fencing, electronic wires, etc., the extrusion process. The basic polymers used in the plastic extrusion process are polyethylene (PE), polypropylene, acetal, acrylic, nylon (polyamides), polystyrene, polyvinyl chloride (PVC), acrylonitrile butadiene styrene (ABS) and polycarbonate.

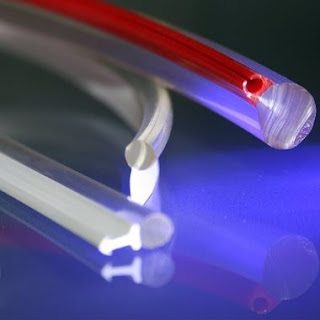

The company that installs these machines reduces human error in manufacturing substances with a complex design. Commodities produced from this manufacturing method are used in a variety of sector. Industries such as automotive, electrical, mining, construction and lifestyle use commodities made through the extrusion process. The pharmaceutical companies demand medical-grade manufacturing facilities; companies need to produce plastic tubes in a clean and antimicrobial place. Generally, doctors use these tubes to deliver fluids into the body.

People in the residential sector are using these products at a high pace. Generally, people having lawns spaces outside their homes like to grow organic vegetables and fruits. People use plastic garden edging materials to avoid smudging of mud inside the house. These objects provide an efficient boundary to the outer layer of the residential and commercial gardening areas.

People can customise the length and size of synthetic objects according to their needs. A person will save a lot of money while purchasing products from these industries. The plastic object manufacturers do not have a large number of labours; their production cost automatically decreases.