Using extrusion profiles in Australia enhances the functionality of products across various industries. These profiles are crafted through cutting-edge techniques and top-quality PVC materials, and offer versatility and customization, for a variety of applications.

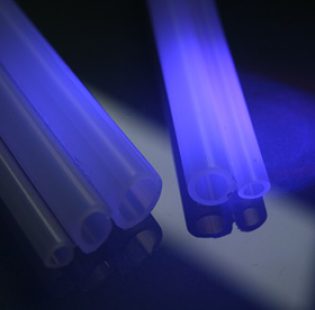

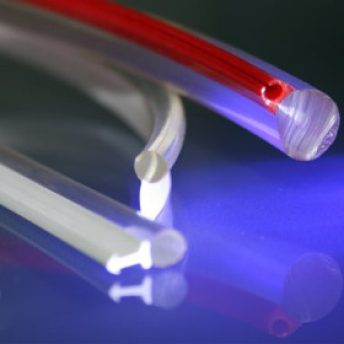

Some leading manufacturers use a range of PVC, and thermoplastic polyurethane, that ensures compatibility with diverse industrial requirements such as LSOH corrugated split tubing, UV-stabilised HDPE solar conduit, LSOH rigid conduit, spiral wrap, poly tubing, flexible PVC, smooth plastic tubing, thin, medium, or dual wall tubing and more.

Importance of Using Extrusion Profiles for Industrial Products:

Well-established extrusion manufacturers are experts in producing seamless extrusions to meet client's needs, from concept to final product. Extrusion profiles serve as integral components in multiple sectors, including automotive, mining, energy storage, and construction.

Their adaptability allows for the creation of complex shapes, such as curtain railings or pipes, tailored to specific needs. Australian industries benefit from enhanced product functionality, durability, and efficiency by using top-quality and innovative extrusion solutions, while meeting stringent quality standards.

- Their extrusion profiles offer flexibility to create various shapes, meeting diverse industrial needs efficiently.

- They deliver tailored products to specific requirements and enhance product functionality and performance.

- These companies use efficient production processes to ensure affordability without compromising quality.

- Resilient materials used in profiles contribute to the longevity and reliability of industrial products.

- They follow a streamlined manufacturing process to enable timely delivery of high-quality, precision-engineered components.

With a commitment to efficient project management and customer satisfaction, well-established extrusion manufacturing specialists continue to drive advancements and success across various sectors in Australia.

Find a Trusted Australian Industrial Extrusion Producing Company:

- Finding a trusted Australian industrial extrusion-producing company needs research both online and offline and through a detailed analysis.

- Buyers should ask for recommendations from industry professionals or online forums.

- Look for companies with a proven track record, industry certifications, and quality assurance measures.

- Evaluate their portfolio, manufacturing capabilities, and client testimonials to ensure they meet customer-specific requirements.

- Additionally, check and compare their reliability, responsiveness, transparency, and customer service by contacting them on call or by email.

Finally, consult with the right manufacturer that is suitable for overall products and services according to the business needs in Australia.